On any job site where heavy loads are lifted and moved, the rigger is one of the most critical team members. Consequently, their expertise directly impacts the safety of everyone on site, the integrity of valuable equipment, and the overall efficiency of the project. Rigging, however, is not a skill learned through guesswork. It is a precise discipline that demands specialized knowledge. This is where professional rigging equipment training becomes absolutely essential. It transforms a workforce from simply being present to being proficient, safe, and compliant.

This comprehensive guide will explore the non-negotiable role of rigging training. We will cover the foundational and advanced skills you’ll acquire. Furthermore, we will answer common questions about qualifications and show you how to find accessible, accredited programs. Ultimately, you will understand why investing in high-quality training is the best decision for your career and your company’s bottom line.

What is Rigging Training and Why Is It Non-Negotiable on the Job Site?

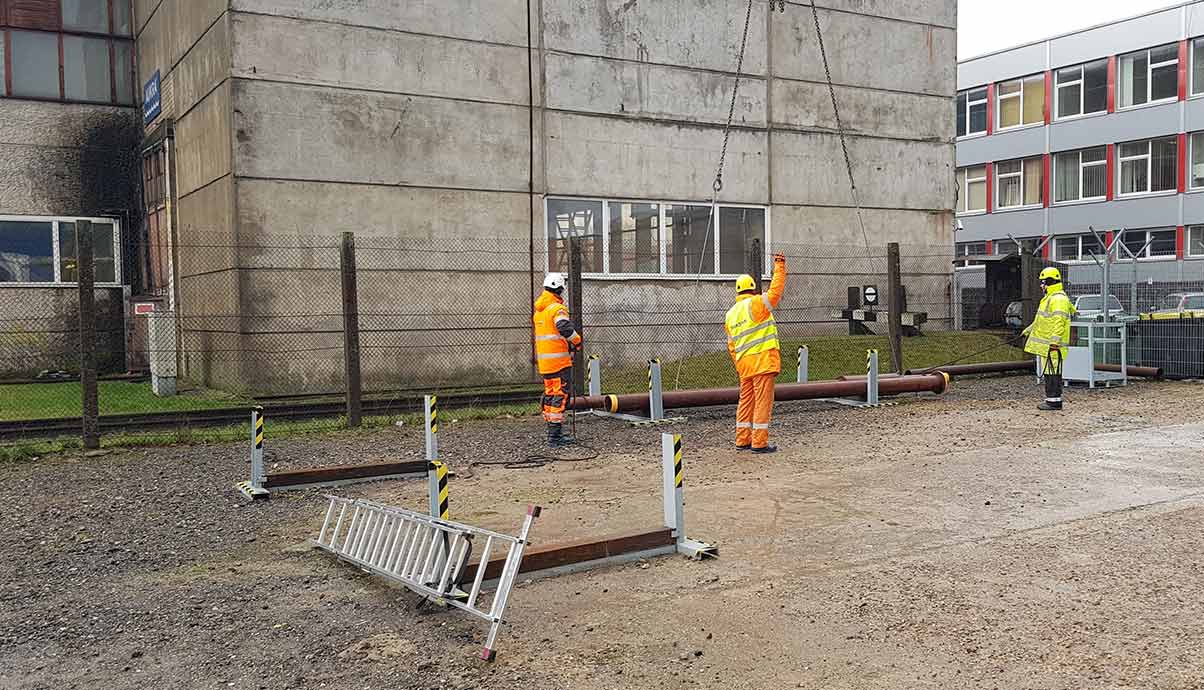

First, let’s define the term. Rigging equipment training is a structured educational program designed to teach workers how to properly inspect, select, and use rigging hardware to safely lift and move heavy loads. Its core purpose is to prevent accidents by equipping individuals with the knowledge to manage the immense forces involved in hoisting operations. Because of the inherent dangers, this training is not just a recommendation; it is a fundamental requirement for a safe and compliant workplace.

The primary goal of this training is to prevent catastrophic failures, ensure compliance with OSHA standards, and protect both personnel and property. A single miscalculation in load weight or a failure to spot a frayed sling can lead to devastating consequences. Therefore, proper training is a non-negotiable line of defense. It instills a deep understanding of safety protocols, turning proactive hazard identification into a reflexive habit for every team member involved in a lift.

You might think only dedicated riggers need this training, but that’s a common misconception. In reality, anyone involved in or supervising lifting operations benefits immensely from this knowledge. This includes crane operators, signalpersons, foremen, safety managers, and even maintenance personnel. When everyone speaks the same language of safety, the entire operation becomes safer. For this reason, osha-crane-training.com provides premier nationwide training solutions that cover essential OSHA regulations and rigging methods for both construction and general industries, ensuring your entire team is aligned on best practices.

Foundational Skills: What You’ll Learn in a Rigging Training Course

A comprehensive rigging training program builds a strong foundation of essential skills. These are the core competencies that every rigger must master to perform their job safely and effectively. The curriculum focuses on practical, hands-on knowledge that can be applied immediately on the job site.

Rigging Hardware and Equipment Selection

A significant portion of training is dedicated to the tools of the trade. You will learn to identify and understand the specific applications for various types of rigging hardware, including different slings (like wire rope, chain, and synthetic), shackles, hoist rings, and turnbuckles. More importantly, the course teaches you how to select the right equipment for a specific lift. This involves considering the load’s weight, shape, and the environmental conditions, ensuring every component can handle the intended stress.

Pre-Use Inspection and Maintenance

Equipment failure is a leading cause of rigging accidents. Because of this, mastering pre-use inspection is a critical skill. Training programs teach you how to meticulously inspect all rigging gear before each use. You will learn to identify signs of wear, such as stretching, corrosion, broken wires, or chemical damage. This proactive approach ensures that compromised equipment is removed from service long before it can fail under load, a key requirement under OSHA regulations.

Load Calculation and Stability

Guesswork has no place in rigging. Therefore, a key part of your training will focus on the physics of lifting. You will learn how to accurately estimate a load’s weight and, just as importantly, determine its center of gravity. Understanding the center of gravity is crucial for preventing a load from tipping or becoming unstable during a lift. In addition, you will learn how sling angles significantly impact the forces exerted on the rigging, a concept that is vital for preventing equipment overload.

Safe Operating Procedures

Finally, all this knowledge is tied together through safe operating procedures. You will master industry best practices for balancing loads, attaching rigging securely, and avoiding dangerous practices like shock loading. The training emphasizes clear communication, controlled movements, and situational awareness. It builds the procedural discipline needed to execute every lift safely, from the most routine to the most complex. These foundational skills are not just about following rules; they are about understanding the principles behind them.

Advanced Skills for the Veteran Rigger

For riggers who have already mastered the fundamentals, continuous education is key to career growth and tackling more challenging projects. Advanced rigging training is designed for these seasoned professionals, focusing on the complexities of non-routine and critical lifts. These courses move beyond the “how” and delve deeper into the “why,” empowering riggers to become lift planners and leaders.

A primary focus of advanced training is comprehensive lift planning. This involves developing detailed, step-by-step plans for unique or high-risk lifts. You will learn to conduct thorough risk assessments, identifying every potential hazard and creating mitigation strategies before the lift even begins. This high-level planning is essential for projects involving extremely heavy, valuable, or asymmetrical loads.

Furthermore, advanced courses refine communication and team coordination skills. While a basic rigger knows the standard hand signals, an advanced rigger masters them, ensuring communication is flawless even in noisy or chaotic environments. They also become proficient in leading pre-lift safety meetings, ensuring every member of the lift team understands their role and the plan.

Finally, you will be introduced to complex rigging techniques. This can include learning how to use multiple cranes for a single lift, calculating forces in complex multi-leg bridle hitches, or safely upending and rotating large objects. These skills are in high demand and are essential for working on large-scale industrial, manufacturing, or construction projects. Even experienced riggers can develop bad habits over time. For this reason, continuous education from experts like osha-crane-training.com reinforces best practices and keeps your skills aligned with the latest industry standards and technologies.

Finding Accessible and Accredited Rigging Training Nationwide

Once you recognize the need for training, the next step is finding a program that is both effective and convenient. Today’s training providers offer a variety of formats to suit different needs, from individual workers to entire corporate teams.

The most popular formats include:

- On-Site Training: For companies looking to train a group of employees, on-site training is often the most efficient option. A qualified instructor comes to your facility, allowing your team to train on the actual equipment they use every day. This format minimizes travel costs and downtime.

- Open Enrollment Courses: These are regularly scheduled classes held at training facilities across the country. They are perfect for individuals or small groups who want to receive expert instruction in a dedicated learning environment.

- Online Courses: For foundational knowledge, online training offers unmatched flexibility. These self-paced courses cover the theoretical aspects of rigging safety, equipment, and regulations, making them an excellent starting point or refresher.

When choosing a provider, it is crucial to select a program that leads to an accredited crane certification. Accreditation ensures the training meets rigorous industry standards and that the qualification you earn is recognized and respected across the country. This formal validation of your skills is what separates a truly qualified rigger from an amateur. With a nationwide network, osha-crane-training.com offers convenient on-site and open-enrollment courses, making it easy to get your team qualified no matter where you operate in the U.S.

The ROI of Rigging Certification: Boosting Careers and Business Safety

Investing in accredited rigging equipment training delivers a powerful return for both the individual and the company. It’s not an expense; it is a strategic investment in safety, efficiency, and professional growth.

For the individual worker, earning a rigging certification is a direct path to career advancement. Certified riggers are in higher demand and often command better pay than their uncertified counterparts. The qualification demonstrates a commitment to safety and professionalism, opening doors to supervisory roles like lead rigger or lift planner. It provides a clear career trajectory in a vital and respected trade.

For the company, the benefits are even more significant. A well-trained team drastically reduces the risk of accidents, which in turn prevents serious injuries, costly equipment damage, and project delays. Moreover, it ensures full compliance with OSHA standards, helping the company avoid steep fines and potential legal liability. A certified team works more efficiently, safely, and confidently, which fosters a positive safety culture that permeates the entire organization. Ultimately, proper training protects your most valuable assets: your people and your reputation.

Answering Your Questions: People Also Ask About Rigging Training

As people explore rigging as a career or a required skill, several common questions arise. Answering them helps clarify the path to becoming a competent and qualified professional.

What are the different levels of rigger qualifications?

The rigging profession often has a tiered structure based on skill and experience. While standards can vary, many programs follow a progression like Rigger Level 1, Level 2, and Advanced or Master Rigger.

- Rigger Level 1 is typically an entry-level qualification. It certifies that an individual can perform simple, repetitive rigging tasks when the load weight, center of gravity, and rigging configuration are known.

- Rigger Level 2 is an intermediate qualification. A Level 2 rigger can select rigging components and procedures based on their knowledge, estimate load weight and center of gravity, and manage more complex lifts.

- Advanced Rigging involves planning and executing non-routine, critical lifts that require a higher level of planning and calculation.

How do you become a qualified rigger?

According to OSHA, a “qualified rigger” is a person who, through a recognized degree, certificate, professional standing, or extensive knowledge and experience, can successfully demonstrate their ability to solve rigging-related problems. In short, you must be able to prove your competence. The most direct path is to complete a formal training and assessment program. For instance, osha-crane-training.com offers robust programs designed to provide you with the knowledge and hands-on skills needed to meet and exceed OSHA’s qualified rigger requirements.

What is the difference between a rigger and a signal person?

Although they work closely together, the roles are distinct. The rigger is responsible for the load itself—they inspect the rigging, determine the attachment points, and connect the load to the lifting device. The signal person, on the other hand, is the crane operator’s eyes and ears on the ground. They are responsible for communicating with the operator via standardized hand signals or radio commands to direct the movement of the load. Both roles are crucial for a safe lift, and both require their own specialized training and qualification.